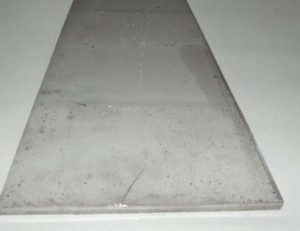

Nickel anodes for electroplating

Not many people understand much about using nickel anodes for electroplating. Most of them are unfamiliar with the electroplating process or the reason for choosing nickel as the anode. As you know, electroplating is a common practice in various industries. The most prominent examples are the automotive industry. The company will use electroplating for the grills and wheels to protect the metal and give a glossy finish.

What is nickel anodes for electroplating ?

Electroplating is a process when a metal sheet receives electrical currents to dissolve and merge other metals into it. The purpose is to add heat and condition resistance to the material. It also will give a better aesthetic to the overall look. The best example of electroplating is having a chrome grill on your car.

A car manufacturer uses electroplating to give the parts shine and resistance. As you know, chrome is corrosive resistant and will take years before finally giving in. It also has this glossy silver look that everyone adores.

There are three available electroplating methods. They are rack, barrel, and electroless plating. With specific pros and cons, the company has to choose one method that suits their needs and gives the best result.

Rack electroplating is perfect for small parts such as automotive gears and medical equipment. In this technique, small parts will receive the electrolytes equally with no surface will be left behind. However, this technique can be expensive for the manufacturer.

The barrel method is a cheaper alternative for rack electroplating. The technique is similar, with the only difference in the plating process. The rotating barrel will move the parts inside to coat the surface equally. The only drawback of this method is the items will bump against each other during the process.

While the name can be confusing, the electroless method doesn’t apply the electric current directly to the metal surface. Instead, this technique uses a chemical reaction by dissolving the plating metal.

Why Nickel anodes?

Nickel anodes for electroplating are an obvious choice because nickel is the easiest metal to blend. As you know, the electroplating process requires anodes and cathodes. As anodes or positive electrons, Nickels can provide protection and other features depending on the industry’s requirements.

Keep in mind that your hard drive has a nickel plate. In case you don’t know, nickel is a magnetic metal. This magnetic plate means hard drives will have enhanced readability and durability. Another example of nickel as anodes is in the aerospace industry.

If hard drives or computer engineering manufacturers use nickel for the magnetic feature. The ones in aerospace engineering use Nickel due to its ability to absorb energy and light. This feature makes nickel the perfect plate for aerospace and defense products. It’s so good that most manufacturers choose this metal to comply with the regulation on industry standards.

You can find more industries using nickel anodes for electroplating. Oil and gas companies, electronic, and even medical items manufacturers use this method in their manufacturing process. Hence, their products have better heat resistance, sturdy material, and anti-corrosion.